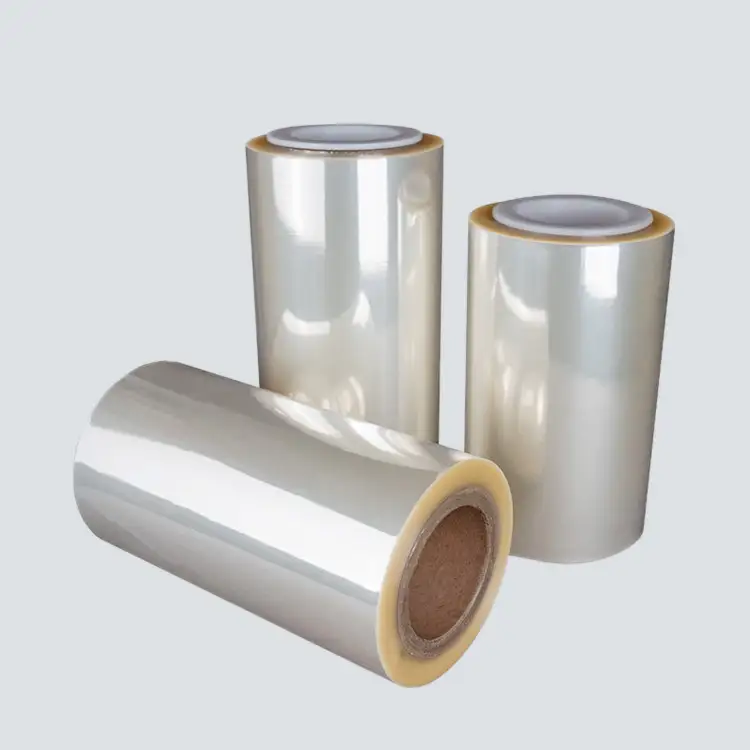

DGN311 Transparent PVC Shrink Film 35mic-50mic

PRODUCT INTRODUCTION

PVC - Polyvinyl Chloride, film shrinks at low temperatures while maintaining its high density. PVC is the most commonly used material. It has good clarity, shrinks at multiple temps, and is very weather resistant. It is also the easiest to control during the process of shrinking while staying scuff resistant. The low cost of pvc shrink sleeves is a plus for most manufacturers and helps us provide lower rates to our buyers. Especially the PVC shrink sleeve film with the following characteristics:

- Excellent Transparency

- Consistent and uniform shrinkage

- Awesome printability

- Resistance to Moisture / Oil

- Excellent toughness and flexibility

- Good shrink ratio

- Fine surface luster

- Great compatibility with all shrink machines

- Low heat required for shrinkage

- Very neat appearance and see through display

- Good lay flat properties

- Effective functioning and speedy operations

PVC Shrink Film is suitable for producing / printing Shrink Sleeves & labels in field of food & beverage, cosmetics, personal care, household product, ect. as follows:

- For full-body sleeves, shrink sleeves and tamper-evident bands

- For wraparound, pressure-sensitive, and roll-on shrink-on labels

- For shrink-wrap multi-packs packaging

With our PVC Shrink Films we offer flexibility in print designs/patterns facilitating the end-customers to successfully promote products & build product image and to use this special packaging medium for introducing new or redesigned products.

Production Process

Raw Material-Mixed Raw Material-Blowing Film-Cutting-Packaging-Warehousing

100% new raw material, stable supplier with stable quality

4 sets Automatic Feeder meets the requirements of the production

During this process, the technician will strictly control the quality (Especially the thickness & shrinkage) according to the customer’s requirement and product stardard.

3 cutting machines, each cutting machine could cut 7 tons per day.

All our film rolls are packed by insulation film for protecting the film from heat and are put horizontally above the pallet (Suspended pallet package). Then Each pallet is also coverd by insulation film.

All ready products will be kept in the air-conditioned room below 25℃.

Technical Data Sheet

Properties | Unit | Data | Test Method | ||

Thickness (Tolerance : ±10%) | μm | 35~50 | ASTM D374 | ||

Density | g/cm² | 1.38 | ASTM D792 | ||

Haze | % | ≤5 | ASTM D1003 | ||

Gloss(45°) | - | ≥90 | ASTM D2457 | ||

Yield | ㎡/kg | 35μm | 20.7 | -- | |

40μm | 18.1 | ||||

45μm | 16.1 | ||||

50μm | 14.5 | ||||

Coefficient of Friction | μs | - | ≤0.60 | ASTM D1894E | |

μk | 0.55 | ||||

Tensile Strength | MD | Mpa | ≥50 | ASTM D882 V=100mm/min | |

TD | ≥42 | ||||

Elongation At Break | MD | % | ≥50 | ||

TD | ≥70 | ||||

Heat Shrinkage (Tolerance : ±3%) | 60℃ | % | 1.4 | 34.7 | ASTM D1204 |

70℃ | 2.1 | 45.2 | |||

80℃ | 2.4 | 47.3 | |||

90℃ | 2.7 | 50.5 | |||

100℃ | 2.9 | 53 | |||

Product Advantages

For over 10 years we have dedicated ourselves to nature and its uniqueness.

Product Application

Poly Vinyl chloride (PVC) shrink film is remarkable for its transparency and easiness of molding, and it is considered as the most commonly used type of shrink film, which could be used in different areas to make the attractive shrink labels:

- Confectionery

- Beverages

- Cosmetics

- Packaged Mineral Water

- stationery

- Pharmaceutical

- Food supplement

- Oil and lubricant

- Electrical products and many more

QUICK LINKS

CONTACT US

E-mail: info@plafilms.com

Mobile / Whatsapp / Wechat:

+86-18327654779

Address: NO. 2003, PINGSHAN AVENUE, LIULIAN COMMUNITY, PINGSHAN STREET, PINGSHAN DISTRICT,SHENZHEN CITY, GUANGDONG PROVINCE

CONNECT WITH US