What conditions does a good quality polymer protective film meet?

by:HYF

2021-02-26

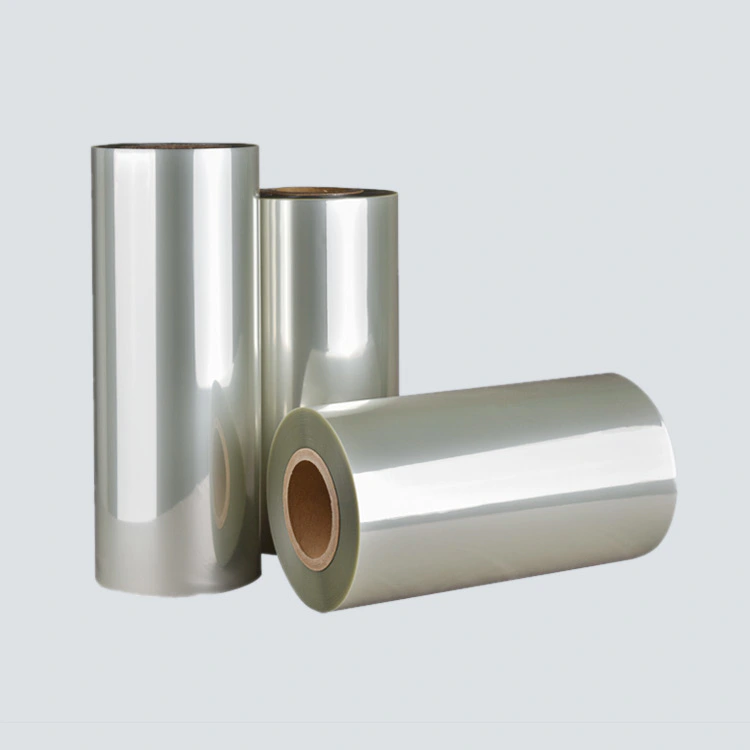

Polymer protective films are constantly emerging in the market, and some manufacturers only pay attention to the price of the protective film, and often overlook the quality of the protective film. The wholesaler of polymer protective film explains what conditions are met to be of good quality. First of all, it has good adhesion to the material to be protected. In the process of material handling and processing, the protective film will not warp or fall off; it has good weather resistance and adhesion stability, and the peeling force after a few days or a long time. The growth is not significant and is easy to remove. The quality of the protective film requires that the mask can withstand it. With proper viscosity, it can be adhered and firmly pasted on the protected body, and it can be removed smoothly. The quality requirements will not increase unnecessary troubles due to brittleness and tearing. The protective film is inert to the surface of the protected material, so that it will not chemically react with the protected product and cause deterioration. Choosing a good quality protective film guarantees sanitation when we use it. Of course, when we use it, we should also pay attention to the fact that the polymer protective film is generally not resistant to high temperatures. Items over ten degrees can be placed cool and sealed with the protective film. Next: The main features of polymer protective filmPrev: How to detect the quality of PE heat shrinkable film

Custom message