What factors affect the quality of heat shrinkable labels?

by:HYF

2021-03-04

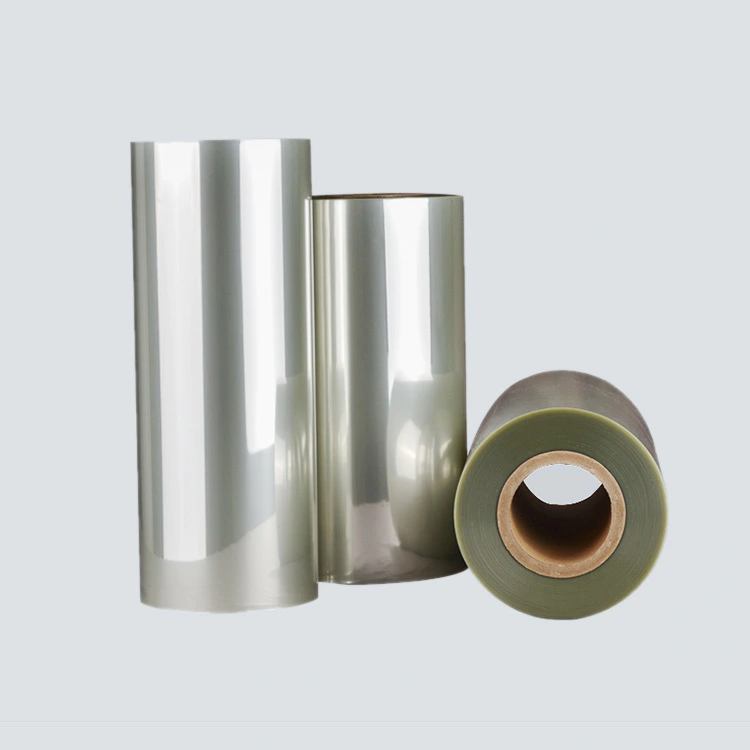

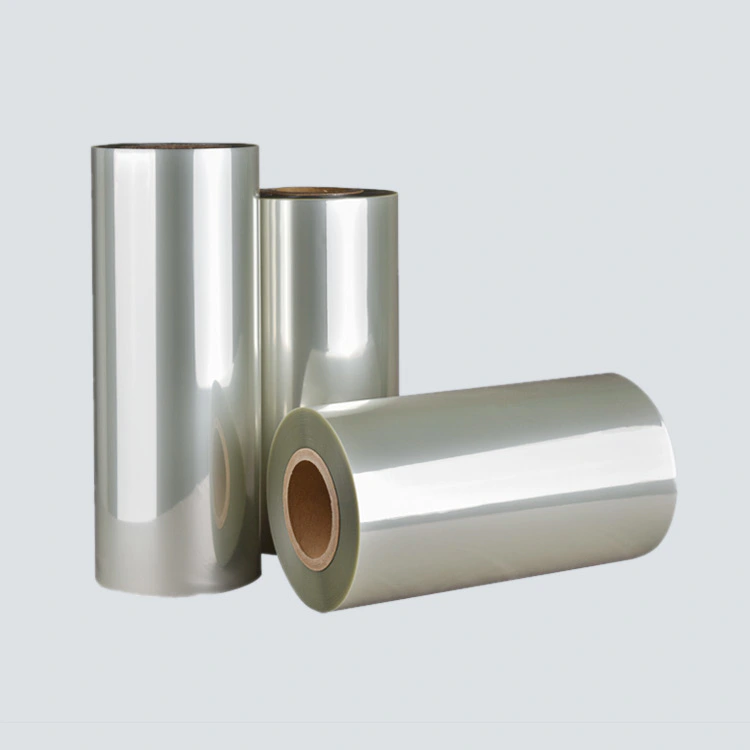

What factors affect the quality of heat shrinkable labels? Release time: 2018-06-23 1. Material thickness. The thickness of the film material is determined according to the application field of the heat shrinkable label, PVC label film, cost, film characteristics, shrinkage function, printing process and labeling process requirements. It is generally required that the film thickness for manufacturing shrink film labels should be 30 to 70 microns, and the commonly used film specifications are 40 microns and 50 microns. In addition to controlling the printing process, the material plays a decisive role in affecting the quality of heat shrinkable labels. Therefore, choosing the right material is the key. So how to choose? 2. Material shrinkage. It is generally required that the shrinkage rate of the film is within the scope of application, and the transverse direction (TD) shrinkage rate is higher than the longitudinal direction (MD) shrinkage rate. The transverse shrinkage rate of commonly used materials for PVC label film is 50%~52% and 60%~62%, and can reach 90% under special circumstances. The longitudinal shrinkage rate is required to be 6% to 8%. When manufacturing shrink film labels, you should try to choose materials with small longitudinal shrinkage. 1. Material thickness. The thickness of the film material is determined according to the application field of the heat shrinkable label, PVC label film, cost, film characteristics, shrinkage function, printing process and labeling process requirements. It is generally required that the film thickness for manufacturing shrink film labels should be 30 to 70 microns, and the commonly used film specifications are 40 microns and 50 microns. 3. Environmental protection of materials. The material used for the heat shrinkable film is mainly a variety of thermoplastic films. At first, PVC shrink film was mainly used. As market demand continues to grow, PET shrink film and PVC (polyvinyl chloride) shrink film are gradually reduced, and all kinds of PE, PP, PET (polyester), PETG (modified polyester), PVDC, OPS (oriented polystyrene), OPP, POF and other multi-layer co-extruded heat shrinkable films grow rapidly and become the mainstream of the market. They have their own characteristics in terms of shrinkage characteristics and environmental protection. Previous: There are two types of heat shrinkable film labels: shrink sleeve label and shrink wrap label.

Custom message