Application range of PE heat shrinkable film

by:HYF

2021-03-04

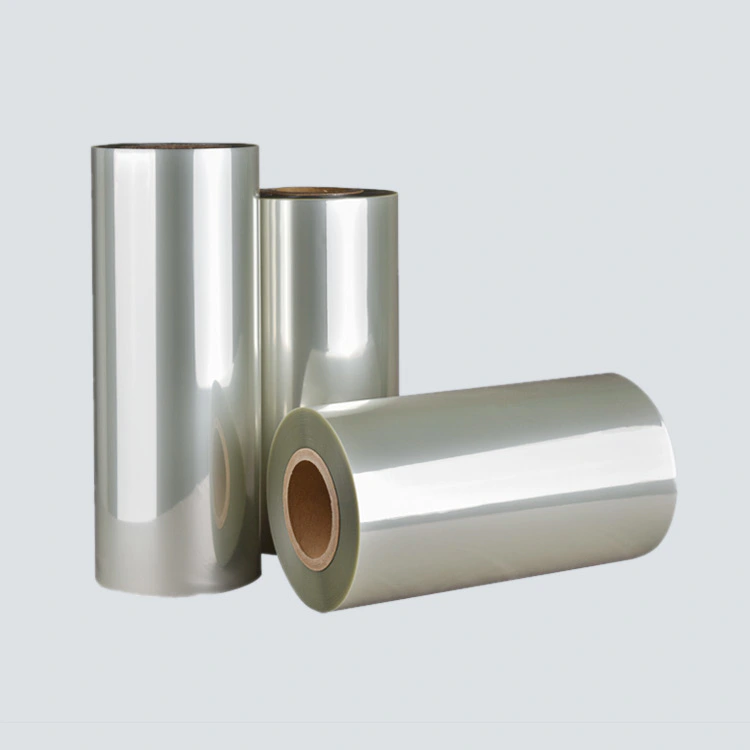

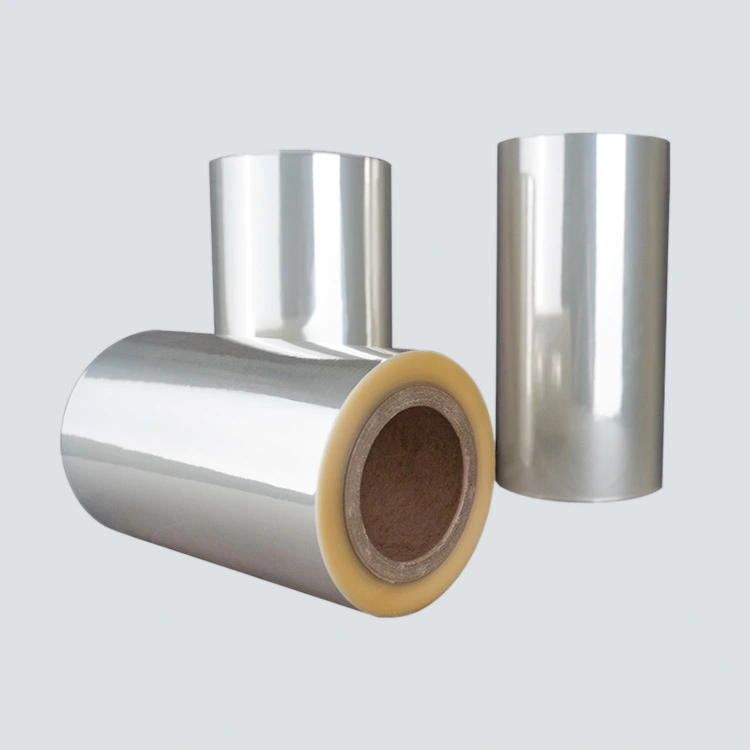

Application range of PE heat shrinkable film Release time: 2019-11-20 Environmentally friendly PE heat shrinkable film, shrink film performance and packaging application effect: 1. Beautiful appearance, can make the film close to the product, so shrink packaging is a kind of skinny Packaging; 2. It can pack goods of various shapes, and it can shrink packaging of various shapes of goods in the same shrink bag, which is convenient to carry; 3. Shrink packaging has good shock resistance, impact resistance, and good protection Performance; 4. Shrink packaging has good cleanliness, can be dust-proof and moisture-proof; 5. The goods in the shrink packaging have good immovability, and the package will not fall in the middle of the package; 6. Good transparency, allowing customers to directly observe Commodity integrity. PE heat shrinkable film application range: medicines, beverages, mineral water, beer, laminate flooring, palletizing, building materials, metal products, dairy products, glass bottles, industrial paper and other large packaging equipment, articles, etc. PE heat-shrinkable film products are industrial-use film packaging products. PE heat-shrinkable film has high tensile strength, high elongation, good self-adhesiveness, and high transparency. It can be used for manual stretch film and machine stretch film, which can be widely used in centralized packaging of various goods. PE shrink film is mainly blended and extruded from several different grades of polyolefin resin. It has puncture resistance, super strength and high performance. It wraps and wraps the goods stacked on the pallet to make the packaging more stable and clean Strong waterproof effect, is widely used in foreign trade, papermaking, hardware, plastic chemicals, building materials, food and medicine industries. Characteristics of heat shrinkable film has high flexibility, not easy to break, strong blast resistance, strong impact resistance, tear resistance, strong tensile force, and can replace box packaging. The shrinkage rate is large, and the items can be tightly wrapped after heat shrinkage. If made into a PE pass-through bag (opening at both ends of the bag) after heat shrinking, the two ends of the opening can lift the items, which can bear a weight of 15KG for easy handling. Good transparency, light transmittance of 80%, can display products, can invisible promotion of products, but also reduce distribution errors in the logistics link. Moisture-proof, waterproof and dust-proof, it can not only achieve the packaging effect, but also beautiful and protect the product. Non-toxic, tasteless, and pollution-free are environmentally friendly packaging materials. The main use of heat shrinkable film: food packaging: fast food, dairy foods, beverages, snacks, beer and various alcohols, agricultural and sideline products, dry food, native products, labels and product sealing; non-food packaging: Labels and seals, fibers and clothing materials, sporting goods, electrical products, pharmaceuticals, grease, detergents, stationery, toys, office supplies, kitchen utensils, daily necessities, miscellaneous goods, construction materials and other packaging. The heat sealing temperature directly affects the heat sealing strength of the heat shrinkable film. During the packaging or bag making process, if the heat sealing temperature is set incorrectly or adjusted incorrectly, the following two situations will occur. 1. When the heat sealing temperature is over When it exceeds the heat shrinkage temperature of the heat shrinkable film surface layer material, it will cause the film to shrink and deform, resulting in adhesion between the shrink film and the heat sealing knife, and the heat sealing edge material melts and extrudes, causing undercutting. 2. When the heat sealing temperature is too low, bad heat sealing will occur. Previous: PVC film production process

Custom message