Main types of heat shrinkable film

by:HYF

2021-03-04

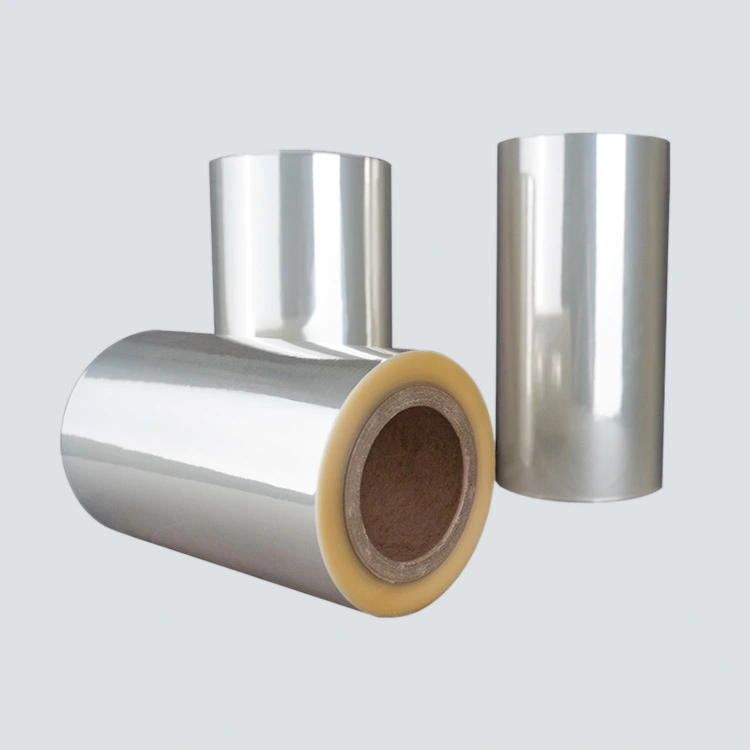

Main types of heat shrinkable film Release time: 2018-10-22 1. The development of heat shrinkable label In the 1970s, Japanese companies introduced advanced technology and made lightweight 330ml carbonated beverage bottle packaging using glass materials. Since glass is easily damaged, in order to make the packaging safer and more reliable, Japanese companies have effectively protected the glass packaging by using OPS heat-shrinkable sleeve labels. Since then, the wave of heat-shrinkable sleeve labels has started, and its market demand has increased significantly. In 1982, in Chicago, USA, Johnson u0026 Johnson's Tylenol capsules were mixed with potassium cyanide, and several deaths occurred, which shocked the society. Under the influence of this incident, no one bought over-the-counter drugs on the American market at that time, and the development of tamper-proof packaging was put on the agenda. Since the production process is not complicated, manufacturers can quickly put into production after introducing equipment, and heat shrinkable sleeve label becomes an effective solution. In 1995, the British SnakeBite beer brand introduced a sleeve label technology applied to small-mouth long-necked glass beer bottles for its new packaging. The promotion of new packaging has unexpectedly opened up more potential new markets. Since then, brand owners have no longer just grasped the color or surface quality of the container itself, their focus has changed from the container to the sleeve label, because the sleeve label can cover the entire surface of the container and becomes a unique method to create a new appearance. This is completely a profound change in thinking. From the above three iconic events, it is not difficult to see that in the past few decades, the heat shrink sleeve label has been inseparable from the strong demand momentum from its birth to its promotion. With the continuous innovation of materials and technology, today's heat-shrinkable sleeve labels have changed the appearance of retail packaging, and have brought packaging to an ever-increasing shelf appeal. Especially with the improvement of environmental awareness, the market share of PETG and BOPS is getting higher and higher. 2. The advantages of heat shrinkable film 1. Heat shrinkable sleeve label mainly adopts gravure printing method. The printed graphics and text are bright in color and good saturation. Because it can decorate the packaging container personally, highlight the appearance of the product and improve the appearance of the product. Sex, can produce good shelf effect. 2. In the labeling process, the label and the container can be integrated without the use of adhesives, which can realize the large-scale connection operation of the product and greatly reduce the production cost. 3. It adopts the back printing method, which can protect the graphics and text and enhance the wear resistance of the heat shrinkable sleeve label in the transportation and sales links. 4. From the perspective of functional requirements, heat-shrinkable sleeve labels have the characteristics of moisture-proof, anti-corrosion, anti-impact, anti-tear, tasteless and non-toxic, and can play an anti-counterfeiting effect. Heat-shrinkable sleeves can also protect consumers from accidental injuries caused by damaged or ruptured containers. 3. Main heat shrinkable film 1. PVC (polyvinyl chloride film) When producing heat shrinkable sleeve labels, the most widely used film material in the market is PVC heat shrinkable film. This kind of film has many advantages such as water resistance, fire resistance, high transparency, high gloss, high shrinkage rate, etc., but the material easily generates toxic gas when burned, which is not conducive to environmental protection. The price is relatively low, but due to environmental problems, the usage is gradually decreasing. Some areas in Southeast Asia are still using it due to economic constraints. General blown film production method, poor transparency, uneven thickness. 2. BOPS, also referred to as OPS (biaxially oriented polystyrene film) as a new material, OPS heat shrinkable film is a kind of skin packaging material that meets environmental protection requirements, with high strength, high rigidity, good gloss and shrinkage rate It has many advantages, such as high and meeting food hygiene standards. However, because there are not many companies that produce this film on the market, it has not been able to fully meet the market demand for this film. From the perspective of the environmental issues of PVC and the recycling of PET containers, the output of OPS as a material that replaces PVC will increase. 'Limited to its own physical and chemical properties, there are problems with poor solvent resistance and poor printability, requiring special ink printing. has a strong tendency of spontaneous shrinkage, requiring stricter storage conditions (low temperature storage, transportation). 3. PETG (modified polyester heat shrinkable film) With the rapid development of PET beverage bottles, various juice beverage bottles such as Coke and Sprite need PETG heat shrinkable film to match it, because they belong to the polyester category. Easy to recycle, it is an internationally recognized environmentally friendly heat shrinkable packaging material. At present, in developed countries, PETG polyester shrink film has become the most ideal alternative material to replace PVC polyvinyl chloride shrink film. Conventional PETG shrinkage rate TD reaches 75%, so it is often used in full-wrapped labels with high shrinkage rate and occasions with environmental protection requirements. It will replace PVC and compete with OPS. Previous: The scope of application of heat shrinkable film

Custom message