OPS (heat shrinkable film) characteristics introduction

by:HYF

2021-03-05

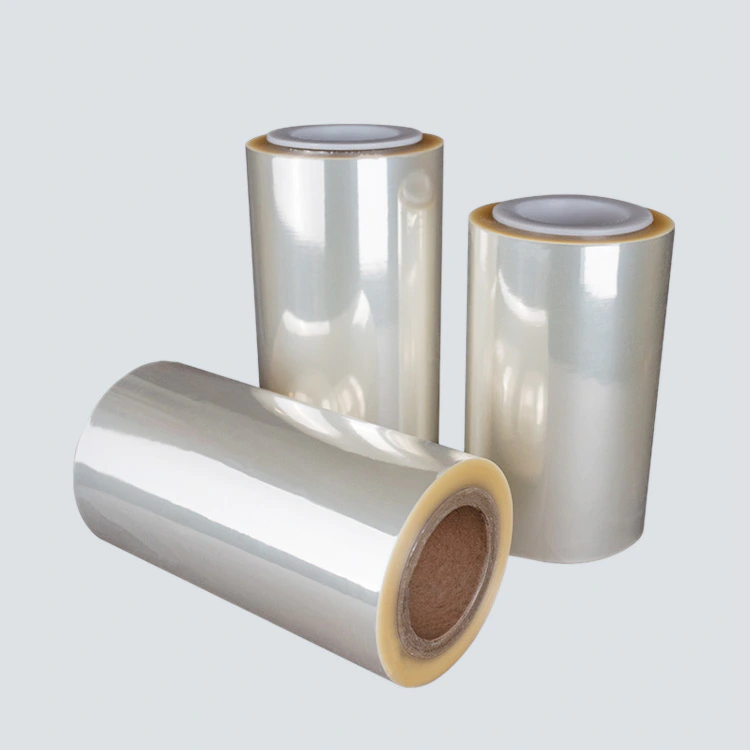

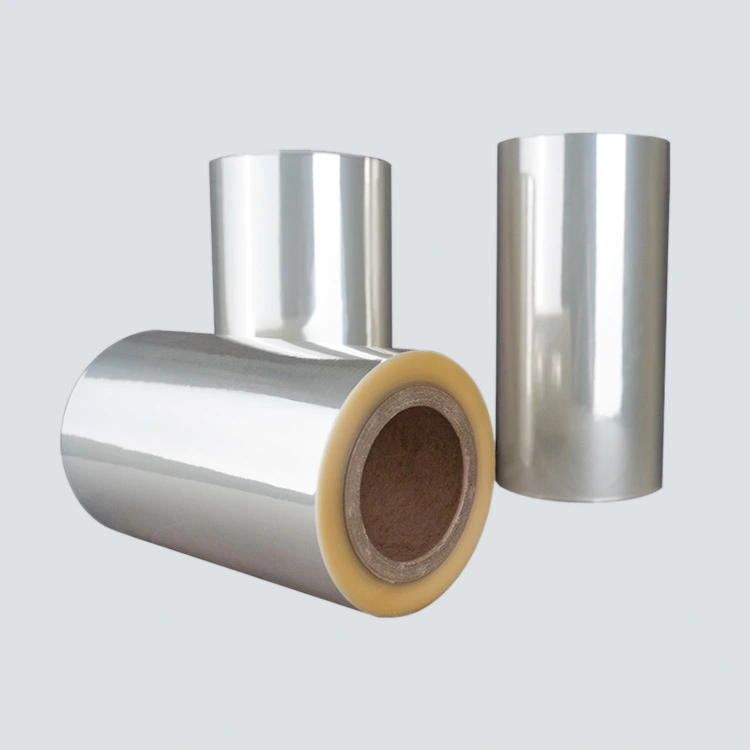

OPS (heat shrinkable film) characteristics introduction Release time: 2016-08-30 OPS (heat shrinkable film) is a new type of skin packaging material that meets environmental protection requirements. OPS heat shrinkable film has high strength, high rigidity, stable shape, and Has good gloss and transparency. Convenient processing, easy coloring, good printing performance, and extremely high printing resolution. For trademarks that are constantly pursuing fine printing, it is completely an improvement in materials. Due to the high shrinkage and strength of OPS film, it can fit closely with containers of different shapes, so it can not only print exquisite patterns, but also meet the use of novel packaging containers with different shapes. A non-toxic, odorless, grease-resistant film that meets food hygiene standards allows designers to use eye-catching colors to achieve a 360° label design, giving full play to creativity and imagination, so that beverages and other products can be on the label The patterns in use are more vivid, highlight the image on the shelf, and produce an unexpected container effect. OPS is a new type of body-mounted printing-grade packaging material that meets international environmental protection requirements. 1) OPS can achieve a lateral shrinkage rate of about 74%, and it is not easy to wrinkle during the shrinking process. The shrinkage can be completed in a non-high temperature environment, so that the heat shrinkable label can be packaged outside the container. After the label is shrunk in the horizontal direction, the label height will hardly be shortened due to the vertical shrinkage in the vertical direction. 2) There is almost no crystallization in OPS. Since OPS resin is different from PVC resin in the raw material refining process, it can greatly reduce the presence of crystal points and foreign matter. 3) OPS is lighter. The specific gravity of OPS is only 1.05. For the three materials of OPS, PVC and PET with the same thickness and area, OPS can reduce the weight by 25%. 4) The tear line made after OPS label shrinks is very symmetrical and easy to tear without destroying the overall effect of the label. The heat shrinkable film is a small heat shrinkable packaging equipment meticulously manufactured in accordance with international standards. It has the characteristics of simple operation, wide application range, good sealing, high transparency, low cost, and high grade. It is suitable for packaging small and medium batch products. The heat shrinkable film machine and the sleeve labeling machine are used online to form a sleeve labeling shrinking machine line, which is widely used in the fully enclosed heat shrinkable packaging of medicines, food, beverages, stationery, ceramics, daily chemicals, auto parts, knitting, electronic audio and video products, etc. , Is the sleeve label shrinking machine of the downstream packaging line. Previous: Introduction of new materials for PET heat shrinkable film

Custom message