Shrink film classification

by:HYF

2021-03-04

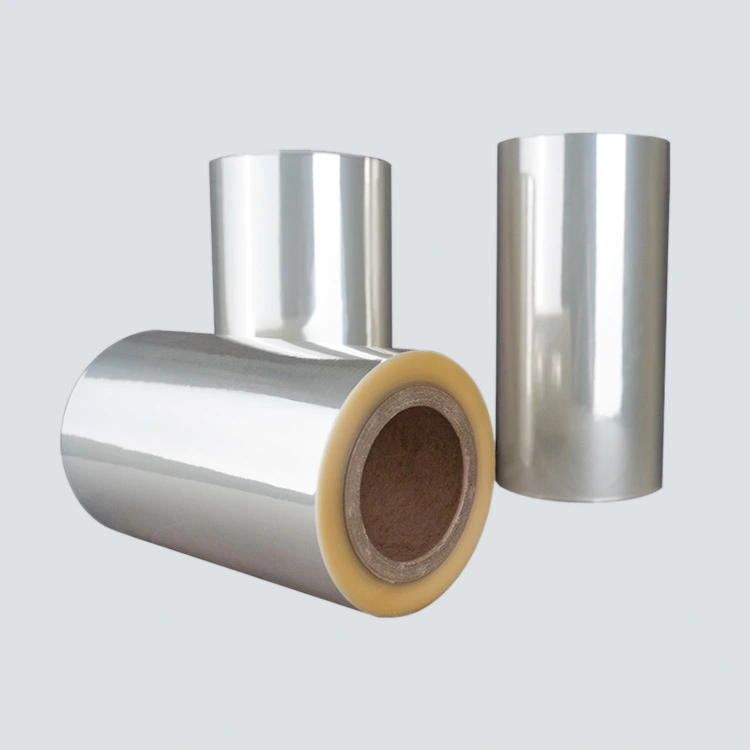

Classification of heat shrinkable film Release time: 2018-10-04 Classification of heat shrinkable film: PE heat shrinkable film PE polyethylene, which is a transparent thermoplastic. There are three types of PE commonly used, namely: LDPE HDPE LLDPE. Heat-shrinkable film PE heat-shrinkable film is widely used in the whole assembly packaging of wine, cans, mineral water, various beverages, cloth and other products. The product has good flexibility, impact resistance, tear resistance, and is not easy Damaged, not afraid of moisture, large shrinkage. PVC heat shrinkable film PVC polyvinyl chloride, with additional ingredients to enhance its heat resistance, toughness, ductility, etc., has a low heat shrink temperature, is cheap, and is very popular. The top layer of this surface film is lacquer, the main component in the middle is polyvinyl chloride, and the bottom layer is back-coated adhesive. It is a kind of synthetic material that is well-loved, popular and widely used in the world today. Among the materials that can produce three-dimensional surface films, PVC is the most suitable material. Because PVC contains chlorine, the chloride produced after burning has a destructive effect on the earth's ozone layer, and it has been gradually used in developed countries. POF heat shrinkable film POF is the meaning of heat shrinkable film. POF stands for multi-layer co-extruded polyolefin heat shrinkable film. It uses linear low density polyethylene as the middle layer (LLDPE) and co-polypropylene (pp) as the inner and outer layers. It is plasticized and extruded by three extruders, and then processed by special processes such as die forming and film bubble inflation. POF is a kind of heat shrinkable film, which is mainly used for packaging products with regular and irregular shapes. It is non-toxic and environmentally friendly, high transparency, high shrinkage, good heat sealing performance, high gloss, toughness, tear resistance, It has the characteristics of uniform heat shrinkage and suitable for automatic high-speed packaging. It is a replacement product of traditional PVC heat shrinkable film. PET heat shrinkable film PET heat shrinkable film is a new type of heat shrinkable packaging material. Because it is easy to recycle, non-toxic, odorless, good mechanical properties, especially in line with environmental protection, polyester (PET) has become an ideal substitute for polyvinyl chloride (PVC) heat shrinkable film in developed countries. However, ordinary polyester is a crystalline polymer, and ordinary PET film can only get a heat shrinkage rate of less than 30% after special processing. To obtain a polyester film with a higher heat shrinkage rate, it must also be modified. In other words, in order to prepare a polyester film with a high thermal shrinkage rate, it is necessary to copolymerize and modify ordinary polyester, namely polyethylene terephthalate. The highest heat shrinkage rate of the PET film modified by copolymerization can be as high as 70% or more. Previous: The powerful role of heat shrinkable labels

Custom message