What are the differences between PE POF heat shrinkable film

by:HYF

2021-03-02

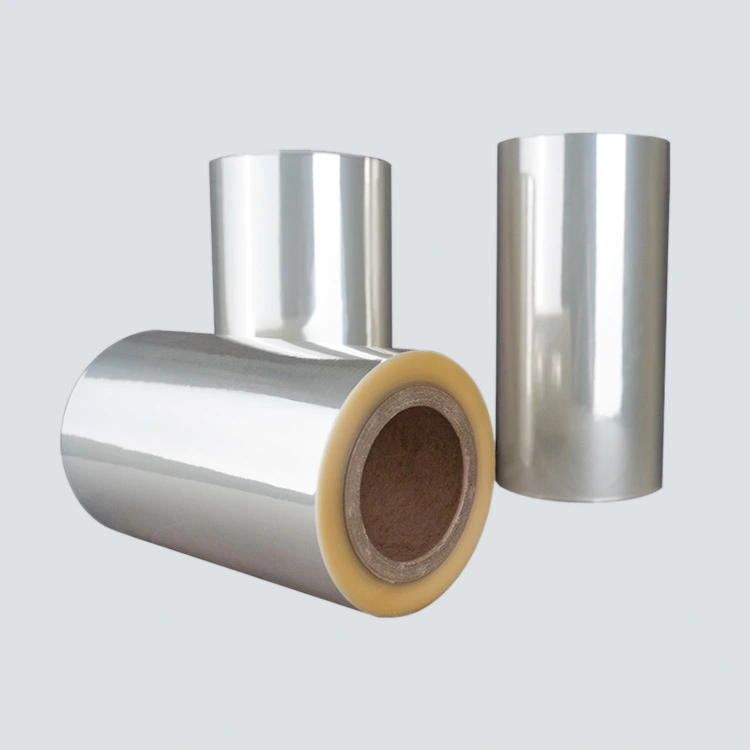

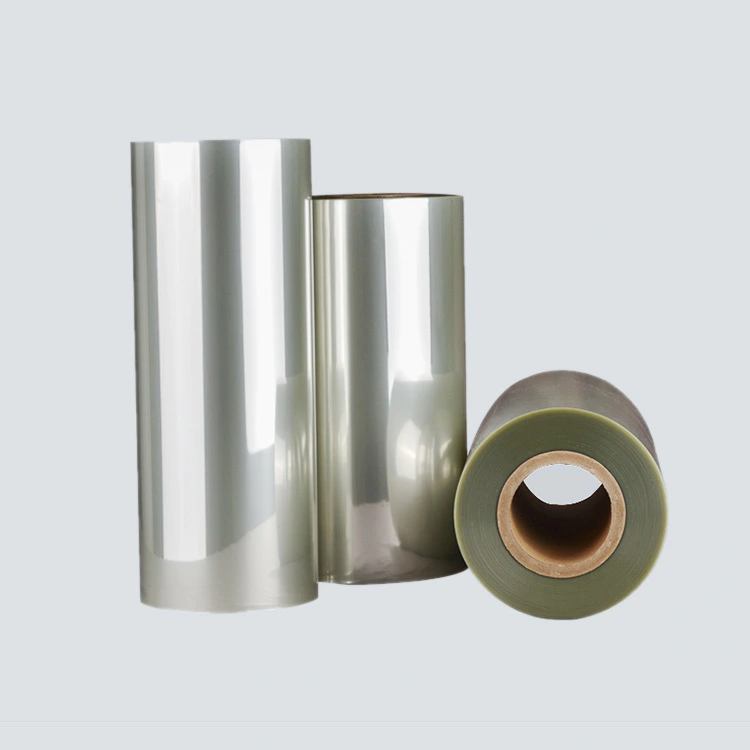

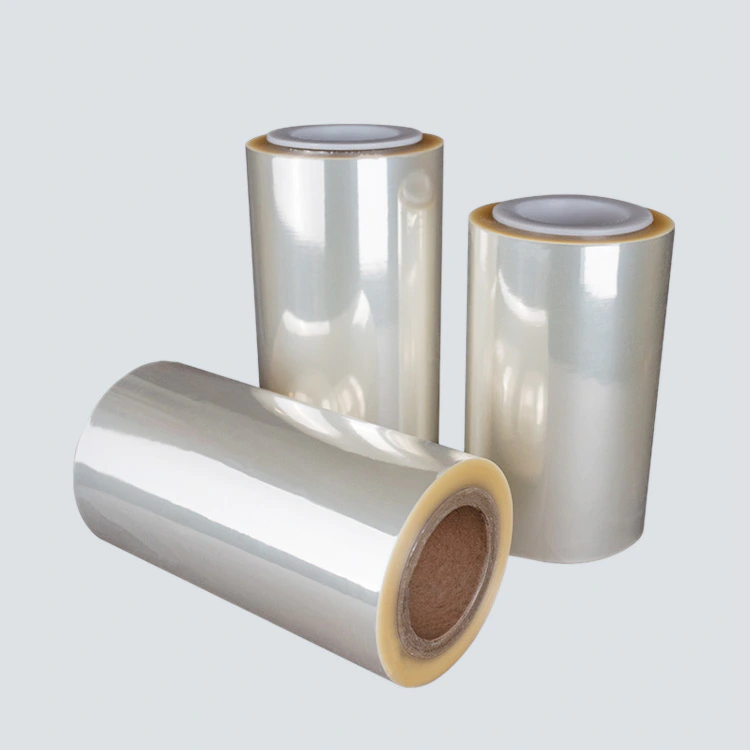

Heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect the product. The shrink film must have high puncture resistance, good shrinkage and a certain shrinkage stress. There are many types of heat shrinkable film, which are used in various fields, so what are the differences between PE/POF heat shrinkable film? PE heat shrinkable film PE polyethylene, it is a transparent thermoplastic. There are three types of PE commonly used, namely: LDPE HDPE LLDPE The monomers of the three kinds of polyethylene are the same, but the process conditions used when synthesizing these polyethylenes are different, so three different polyethylenes are produced Varieties, the properties of the three materials are quite different. PE film is a material with very good toughness, and it is not easy to crush with ordinary plastic crushers. Because the PE film is soft and tough, it is not easy to be shredded, not to mention the high temperature of the tool at high speed, which will cause the LDPE to melt and adhere to the blade. PE pelletizing can be directly put into the feeding port of the extruder into strips, and the PE film is dragged into the barrel by the shearing force of the screw to heat, melt, and extrude pellets. PE recycled first-grade materials can still be blown film, used for non-food and pharmaceutical packaging, and also widely used in the production of Oxford leather and tarpaulin, with a bright future. PE heat shrinkable film is widely used in the whole assembly packaging of wine, cans, mineral water, various beverages, cloth and other products. The product has good flexibility, impact resistance and tear resistance, and is not easy to break and fear. Moisture and high shrinkage rate. POF heat shrinkable film POF is the meaning of heat shrinkable film. POF stands for multi-layer co-extruded polyolefin heat shrinkable film. It uses linear low density polyethylene as the middle layer (LLDPE) and co-polypropylene (pp) as the inner and outer layers. It is plasticized and extruded by three extruders, and then processed by special processes such as die forming and film bubble inflation. POF is a kind of heat shrinkable film, which is mainly used for packaging products with regular and irregular shapes. It is non-toxic and environmentally friendly, high transparency, high shrinkage, good heat sealing performance, high gloss, toughness, tear resistance, It has the characteristics of uniform heat shrinkage and suitable for automatic high-speed packaging. It is a replacement product of traditional PVC heat shrinkable film. It is widely used in automotive supplies, plastic products, stationery, books, electronics, circuit boards, MP3, VCD, handicrafts, photo frames and other wood products , Toys, pesticides, daily necessities, food, cosmetics, canned drinks, dairy products, medicine, cassettes and video tapes and other products. Previous: Announcement on the resumption of work after the epidemic Next: Specific gravity and viscosity of PE stretch film

Custom message