Wuhan heat shrinkable film manufacturers: various characteristics of heat shrinkable film

by:HYF

2021-03-02

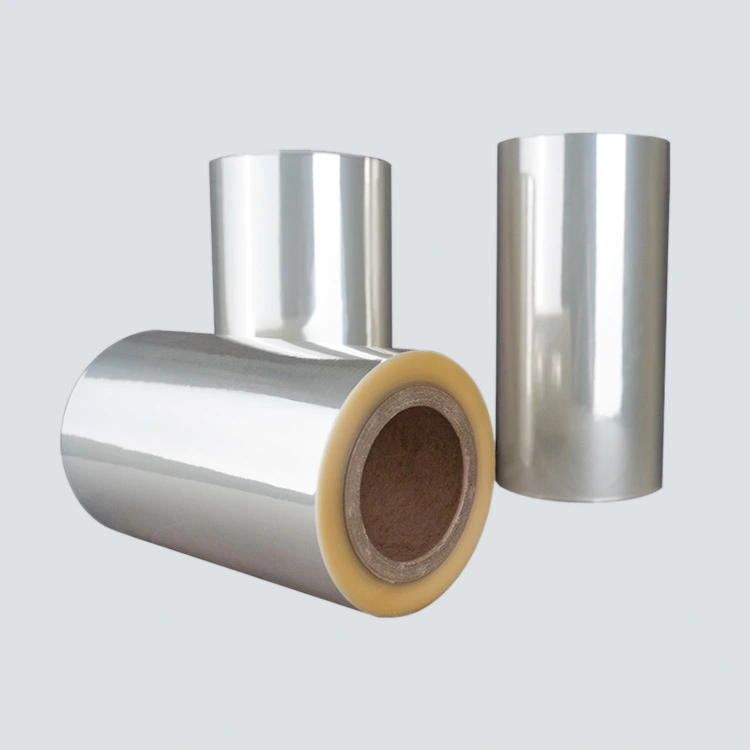

PE shrink film PE polyethylene, it is a transparent thermoplastic. There are three types of PE commonly used, namely: LDPE HDPE LLDPE The monomers of the three kinds of polyethylene are the same, but the process conditions used when synthesizing these polyethylenes are different, so three different polyethylenes are produced Varieties, the properties of the three materials are quite different. PE film is a material with very good toughness, and it is not easy to crush with ordinary plastic crushers. Because the PE film is soft and tough, it is not easy to be shredded, not to mention the high temperature of the tool at high speed, which will cause LDPE to condense and adhere to the blade. PE pelletizing can be directly put into the feeding port of the extruder into strips, and the PE film is dragged into the barrel by the shearing force of the screw to heat, melt, and extrude pellets. PE recycled first-grade materials can still be blown film, used for non-food and pharmaceutical packaging, and generally used in the consumption of Oxford leather and tarpaulin. The way forward is bright. PE heat-shrinkable film is generally suitable for the whole assembly packaging of wine, cans, mineral water, various beverages, cloths and other products. The product has good flexibility, impact resistance, tear resistance, and is not easy to break and fear. PVC shrink film with high moisture and shrinkage rate, and additional ingredients to enhance its heat resistance, toughness, ductility, etc. The top layer of this surface film is lacquer, the main component in the middle is polyvinyl chloride, and the bottom layer is back-coated adhesive. It is a kind of synthetic material that is very popular, popular and widely used in the world today. Among the materials that can consume three-dimensional surface films, PVC is the most suitable material. Due to the common properties of PVC (rain resistance, fire resistance, anti-static, easy to shape) and low input and high output characteristics of PVC, it is widely used in building materials industry and packaging industry. Therefore, PVC film has high transparency, good gloss and shrinkage. High rate characteristics. POF shrink film POF has high surface gloss, good toughness, high tear strength, uniform heat shrinkage and suitable for automatic high-speed packaging. It is a replacement product of traditional PVC heat shrinkable film. POF is the meaning of heat shrinkable film. POF stands for multi-layer co-extruded polyolefin heat shrinkable film. It uses linear low-density polyethylene as the middle layer (LLDPE) and co-polypropylene (pp) as the inner and outer layers. It is plasticized and extruded out of the machine, and then processed by special processes such as die forming and film bubble inflation. Previous: Look at the practical characteristics of heat shrinkable film labels for beverage bottles Next: Common problems and solutions for the use of PVC heat shrinkable film (2)

Custom message