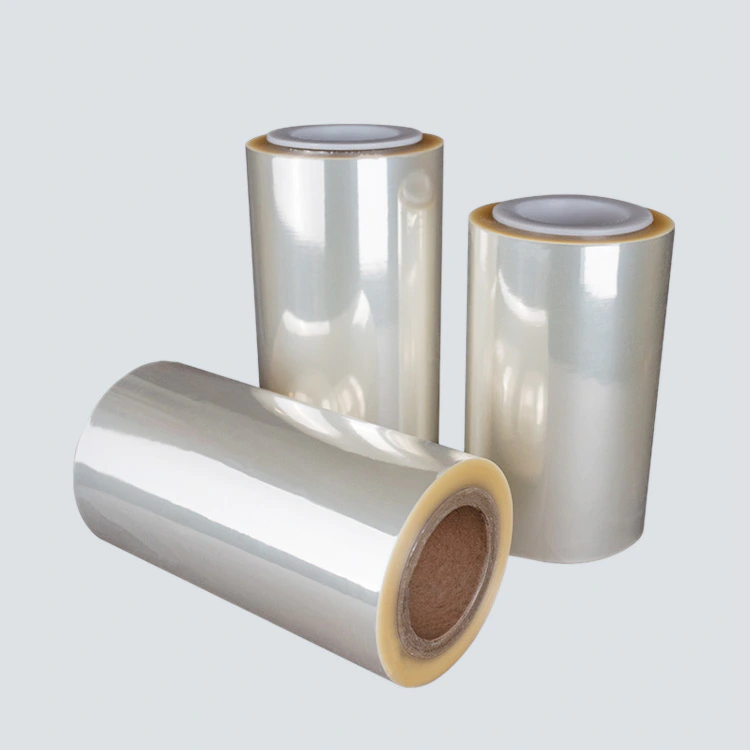

Characteristics and application of PE stretch film

by:HYF

2021-03-02

PE stretch film characteristics: 1. Packed by manual operation, a single roll weighs 3 to 5 kg, which is convenient for manual operation. 2. Strong stretchability, pre-stretching rate of more than 300%, which can save materials; 3. Non-toxic, environmentally friendly, moisture-proof, waterproof, dustproof, anti-corrosion, anti-theft, anti-collapse; 4. Anti-puncture and anti-tear Strong cracking performance, to ensure that the film will not be pierced even when there are sharp goods; 5. Durable shrinkage memory; 6. Stable and reliable self-adhesiveness; 7. High transparency, which is conducive to the identification of goods; PE stretch film application method : 1. Sealed packaging. This packaging is similar to shrink film packaging. The film wraps the tray around the tray, and then two thermal grippers heat seal the two ends of the film together. This is the earliest use of stretch film, and more packaging methods have been developed from it. 2. Full-width packaging requires that the film width is sufficient to cover the pallet, and the shape of the pallet is regular, so it has its own application and suitable film thickness. It is 17~35μm 3. Manual packaging This kind of packaging is the simplest kind of stretch film packaging. The film is mounted on a rack or hand-held, rotated by the tray or the film is rotated around the tray. It is mainly used for repacking after the wrapped pallet is damaged, and ordinary pallet packaging. This kind of packaging speed is slow, and the suitable film thickness is 15-20μm; 4. Stretch film wrapping machine packaging This is a *general* common mechanical packaging method. The film is fixed in The bracket can be moved up and down. This kind of packaging can be very large, about 15-18 trays per hour. The suitable film thickness is about 15~25μm; 5. Horizontal mechanical packaging is different from other packaging. The film revolves around the goods, which is suitable for long goods packaging, such as carpets, boards, fiberboards, special-shaped materials, etc.; 6. Paper tube Packaging This is one of the best uses of stretch film, which is better than the old-fashioned paper tube packaging. The suitable film thickness is 30~120μm; 7. Packaging of small items This is the best packaging method of stretch film, which can not only reduce data consumption, but also reduce the storage space of pallets. In foreign countries, this kind of packaging was first introduced in 1984. Just one year later, many such packaging appeared on the market, and this packaging method has great potential. Suitable film thickness is 15~30μm; 8. Packaging of tubes and cables. This is an example of the application of stretch film in special fields. The packaging equipment is installed in the ** of the consumer line. The complete automatic stretch film can replace the tape to bind the materials, and Can play a maintenance role. The applicable thickness is 15-30μm. 9. The stretching method of pallet mechanism packaging All stretch film packaging must be stretched. The stretching methods of pallet mechanical packaging include direct stretching and pre-stretching. Pre-stretching is divided into two types, one is roll pre-stretching and the other is electric stretching. Direct stretching is to complete the stretching between the tray and the film. This method has a low stretching ratio (about 15% to 20%). If the stretching ratio exceeds 55% to 60%, it exceeds the original compliance point of the film, the film width is reduced, and the puncture performance is also lost. Easy to break. And at 60% stretch rate, the pulling force is still very large, as for light goods, it is likely to deform the goods. The pre-stretching is done by two rollers. The two pre-stretching rollers of the roller are connected together by a gear unit. The stretching ratio can be different according to the gear ratio. The tension is generated by the turntable. Since the stretching is generated in a short interval, the friction between the roller and the film It is large, so the film width does not shrink, and the original puncture performance of the film is maintained. There is no stretching in practice during winding, which reduces the breakage caused by sharp edges or corners. This pre-stretching can increase the stretching ratio to 110%. The stretching mechanism of electric pre-stretching is the same as that of roll pre-stretching. The difference is that the two rolls are driven by electricity, and the complete stretch has nothing to do with the rotation of the tray. Therefore, the compliance is stronger, and light, heavy, and irregular goods are applicable. Due to the low tension during packaging, the pre-stretching ratio of this method is as high as 300%, which greatly saves materials and reduces costs. The suitable film thickness is 15-24μm. Previous: Specific gravity and viscosity of PE stretch film Next: Characteristics of POF environmental protection shrink film

Custom message